Определяем комплектацию по VIN

Вы можете написать сейчас и зарегистрироваться позже. Если у вас есть аккаунт, авторизуйтесь, чтобы опубликовать от имени своего аккаунта.

- Владимир 2515

- Купил Порося

- naran

- Psix

- Rasck

- Землянин

- SergeySemenov

- National

- Краматорск_Андрей

- MikeGCh

- Boltzx

- Trail_Rated

- serg102

- Алексей ухта

Бортжурналы

Jeep Grand Cherokee Trailhawk 2017

Последние записи

Течь расширительного бачка

Эпопея с системой охлаждения!

О замене бачка писал, опишу проблему подробнее, возможно кому-то пригодится.

Из бачка стал уходить антифриз, видимых потёков не было, я напрягся и стал наблюдать.

Смотрел на уровень в бачке после ночной стоянки, система ж должна остыть, давление выровняться. Во время пуска двигателя смотрел на выхлопные газы. Почитал статьи про систему охлаждения, все пишут про прогоревшие прокладки, в общем жуть. Продолжалось это несколько месяцев. Антифриз периодически уходил, а я его подливал. Однажды поднял капот сразу после поездки по городу и вижу блестит коса проводов, которая проходит примерно под бачком. Трогаю её пальцем — палец красный. Думаю вот оно. Начинаю лазить искать. Включил фронтальную камеру на телефоне и засунул телефон под бачок, а там висит капля и дренажная трубка мокрая.

Всё вытер, выровнял уровень в бачке и стал ждать. А антифриз не уходит.

В итоге моих наблюдений оказалось, что на самом дне бачка, в самой его нижней точке, похоже образовалась микротрещина. При езде по городу, когда система охлаждения максимально разогревалась и создавалось максимально высокое давление, бачок начинал течь. Но тёк не сильно, поэтому до утра в подкапотном всё высыхало.

При этом автомобиль 2017 года, какого хрена бачок треснул непонятно.

Поставил новый бачок, заменил на нём крышку, и уже как порядка 2000 км этой проблемы нет. Но фобия осталась и литр антифриза всегда лежит в багажнике.

Всем добра и крепких бачков!

WK2 Содержание VIN кода (англ.)

Вы можете написать сейчас и зарегистрироваться позже. Если у вас есть аккаунт, авторизуйтесь, чтобы опубликовать от имени своего аккаунта.

- Владимир 2515

- Купил Порося

- naran

- Psix

- Rasck

- Землянин

- SergeySemenov

- National

- Краматорск_Андрей

- MikeGCh

- Boltzx

- Trail_Rated

- serg102

- Алексей ухта

Бортжурналы

Jeep Grand Cherokee Trailhawk 2017

Последние записи

Течь расширительного бачка

Эпопея с системой охлаждения!

О замене бачка писал, опишу проблему подробнее, возможно кому-то пригодится.

Из бачка стал уходить антифриз, видимых потёков не было, я напрягся и стал наблюдать.

Смотрел на уровень в бачке после ночной стоянки, система ж должна остыть, давление выровняться. Во время пуска двигателя смотрел на выхлопные газы. Почитал статьи про систему охлаждения, все пишут про прогоревшие прокладки, в общем жуть. Продолжалось это несколько месяцев. Антифриз периодически уходил, а я его подливал. Однажды поднял капот сразу после поездки по городу и вижу блестит коса проводов, которая проходит примерно под бачком. Трогаю её пальцем — палец красный. Думаю вот оно. Начинаю лазить искать. Включил фронтальную камеру на телефоне и засунул телефон под бачок, а там висит капля и дренажная трубка мокрая.

Всё вытер, выровнял уровень в бачке и стал ждать. А антифриз не уходит.

В итоге моих наблюдений оказалось, что на самом дне бачка, в самой его нижней точке, похоже образовалась микротрещина. При езде по городу, когда система охлаждения максимально разогревалась и создавалось максимально высокое давление, бачок начинал течь. Но тёк не сильно, поэтому до утра в подкапотном всё высыхало.

При этом автомобиль 2017 года, какого хрена бачок треснул непонятно.

Поставил новый бачок, заменил на нём крышку, и уже как порядка 2000 км этой проблемы нет. Но фобия осталась и литр антифриза всегда лежит в багажнике.

Всем добра и крепких бачков!

Jeep WK2 Grand Cherokee VIN Decoding and Build Sheets

Welcome to the JeepSpecs.com in-depth page on the WK2 Jeep Grand Cherokee VIN decoding and build sheets. Did we miss anything? get in touch with us and let us know!

Sample 2011 Grand Cherokee VIN number

| The Vehicle Identification Number (VIN) plate is attached to the top left side of the instrument panel. The VIN contains 17 characters that provide data concerning the vehicle. Refer to the decoding chart below to determine the identification of a vehicle. To protect the consumer from theft and possible fraud the manufacturer is required to include a Check Digit at the ninth position of the Vehicle Identification Number. The check digit is used by the manufacturer and government agencies to verify the authenticity of the vehicle and official documentation. The formula to use the check digit is not released to the general public. |

| VIN # | 1 | J | 4 | R | S | 4 | G | G | X | B | C | 5 | 0 | 1 | 5 | 4 | 8 |

| Position | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 |

| Interpretation | C O U N T R YO RM F R | M A K E | V E H I C L ET Y P E | G V W R | V E H I C L EL I N E | S E R I E S | B O D YS T Y L E | E N G I N E | C H E C KD I G I T | M O D E LY E A R | A S S E M B L YP L A N T | 6-digit vehicle serial number | |||||

Vehicle Identification Number decoding chart

Vehicle Identification Number decoding chart

Vehicle Identification Number decoding chart

Vehicle Identification Number decoding chart

Vehicle Identification Number decoding chart

Vehicle Identification Number decoding chart

Vehicle Identification Number decoding chart

Vehicle Identification Number decoding chart

Vehicle Identification Number decoding chart

Vehicle Identification Number decoding chart

Vehicle build stages

After the design is complete, there are three builds in the process called S0, S1 and S2. As the first attempt, the SO is used to identify potential issues. This is where the Error Mistake Proofing (EMP) process kicks in.

The S0 is the first build attempt and is supposed to be completely production representative. This initial build is not at the plant; it is at a pilot facility with a lot of the same equipment that will be used at the plant. Employees from the plant, known as a pilot team, are brought in to look at the process and determine if there is a more effective way to build the vehicle or design the parts.

The S1 is the second level of production. Everything is supposed to be as close to production as possible and it has modifications that were discovered and changed during S0. S2 is the final build stage and is done right before launch.

For the 1999 Grand Cherokee there were 32 employees assigned to the Pilot team. The team works on the prototype builds of the vehicle, evaluates the assembly process and suggests how the parts could be improved. They also stay with the vehicle all the way from the first “SO” build through the launch. Some members of the team will continue to work on training and making improvements throughout the rest of the model year.

Once the vehicle is set for launch there is a ramp-up process that occurs. All of the components are brought to the line in time to build the vehicles as they start to come down the assembly line. Production starts out slowly and is accelerated in the days or weeks following.

Body Code Plate

A metal Body Code plate is located in the engine compartment and attached to the top of the right frame rail. The information listed on the plate is used for manufacturing and service purposes. Information on the plate includes whether the vehicle is Domestic or export, the Primary and Secondary paint codes, frame sequence number and internal manufacturing codes.

Grand Cherokee paint codes can be found on our Exterior colors page.

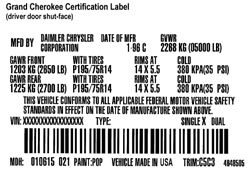

Vehicle Certification Label

A vehicle safety certification label is attached to every Chrysler Corporation vehicle. The label certifies that the vehicle conforms to all applicable Federal Motor Vehicle Safety Standards. The label is located on the driver-side door shutface.

On the example above, “Date of MFR” is listed as “1-96” which is “January 1996”. At the bottom left of the plate the Month, Day and Hour of manufacturer is listed as “MDH 010615”, this means that the vehicle was built January (“01”), 6th (“06”) at 3:00PM (“15”).

Month and year of vehicle manufacture.

Gross Vehicle Weight Rating (GVWR). The gross front and rear axle weight ratings (GAWR’s) are based on a minimum rim size and maximum cold tire inflation pressure.

Vehicle Identification Number (VIN)

Type of vehicle

Type of rear wheels

Bar code

Month, Day and Hour (MDH) of final assembly

Paint and Trim codes

Country of origin

Vehicle build sheets

Vehicle build sheets are forms that list all of the colors, features and options of a particular vehicle along with the corresponding sales codes. The top of the form lists the Vehicle Identification Number, model year, model family, build date and trim color. Every single feature and option is noted, if a particular item is not listed then it did not come equipped that way from the factory. Dealer add-on accessories are not included on build sheets.

Build sheets can be obtained from your local dealer by presenting your VIN number and requesting a printout. Build sheets can be very handy when trying to determine color or option codes for ordering replacement parts and accessories. In addition, when shopping for a used vehicle, build sheets can provide a complete list of the vehicle options. They may also show if a vehicle was originally sold to a rental company.

| Vehicle Build Sheet – example data | |||||

| VIN | 1J8HR58J95C083005 | ||||

| Model Year | 2005 | ||||

| Family | WK | ||||

| Engine | EZB – Engine-5.7L Hemi Multi Displacement | ||||

| Market | USA | ||||

| Body Model | JP74 – JEEP GRAND CHEROKEE LIMITED 4X4 4WD 109.5 | ||||

| Build Date | 2004-02-24 | ||||

| Trim | *PL – Seats – Leather Trimmed Bucket | ||||

| Trim Color | -J1 – Dk Khaki/Lt Graystone | ||||

| Sales Codes (partial list) | |||||

| *PL | Seats – Leather Trimmed Bucket | ||||

| -J1 | Dk Khaki/Lt Graystone | ||||

| 191 | Zone 91-Drop Ship | ||||

| 25K | Customer Preferred Package 25K | ||||

| 2TK | Customer Preferred Package 2TK | ||||

| 32F | Limited Equipment Discount | ||||

| 4BD | Vehicle Order Tracking | ||||

| 5YC | WK-Vehicle Family | ||||

| 5I4 | Four Wheel Drive (4WD) | ||||

| A55 | 5.7L Eng(EZB)/5Spd A/T 545RFE(DGQ) | ||||

| ADL | Skid Plate Group | ||||

| AEK | Electronic Infotainment Sys Group | ||||

| AFF | Luxury Group | ||||

| APA | Monotone Paint | ||||

| AWB | Quadra-Drive 4WD System | ||||

| BAB | Alternator – 160 Amp | ||||

| BCN | Battery – 730 Amp Maintenance Free | ||||

| BRY | Brakes – Anti-Lock 4-Wheel Disc | ||||

| CAC | Seats – Low Back Bucket | ||||

| CBF | Door Trim Panel – Premium | ||||

| CG6 | Seat Belt – Rear Center, 3-Point | ||||

| CHB | Headliner – Cloth Covered | ||||

| DHX | Quadra-Trac II Full-Time,Active 4WD | ||||

| DSG | Axle-Elec LTD Slip Differential,Frt | ||||

| HGF | Insulation – Floor Tunnel | ||||

| HGA | Insulation – Hood | ||||

Vehicle Order Number (VON) and vehicle tracking

Once a special order is placed for a vehicle, a document is generated that details the vehicle and exact options that you want. A VON (Vehicle Order Number) is assigned that will allow tracking of your vehicle until it gets assigned a VIN (Vehicle Identification Number).

To obtain the current order status of your vehicle:

2. The input sequence is 6, 2, 1, 2, and then your phone number, then 1. This brings you to an operator who can give you details on the status of your order. A complete list of Order Status Codes is shown in the table below.

E – framing

F – paint

G – trim

I – unit is pending final inspection

J – vehicle has passed final inspection, but has not been released to carrier

JB – shipped to body vendor

JE – shipped to emissions

JJ – consigned body vendor

JS – shipped to storage

KZ – released by plant and invoiced

Note: Vehicles must reach KZ-status before an invoice can be generated.

KZ L – released but not shipped

KZ LD – in transit, delayed

KZ M – in transit, first rail departure

KZ N – first rail arrival

KZ O – delayed/received, in transit issues

KZ OA – plant hold, quality audit

KZ OB – zone or dealer hold, sales hold, vehicle prep hold, tax hold, finance hold, dealer refusal, diversion hold, vehicle diverted, derailment hold

KZ OC – carrier delay hold, rail car shortage, bad load, insufficient load, inclement weather, need shipping order, manifest error, strike-bound hold, emission or safety hold.

KZ OD – mechanical failure, glass damage, vehicle lacking parts, vehicle in repair, storage hold

KZ OE – misdropped or misshipped vehicle

KZ OF – shipped air freight, stolen vehicle recovered, show vehicle, test info code, vessel sailed

KZ OG – damaged vehicle, stolen vehicle, abandon to carrier, vehicle scrapped, donate vehicle, repair and auction

KZ OH – all other carrier codes that currently post an “O” delay code that are not included above

KZ P – arrived at Body Vendor / upfitter

KZ Q – completed at ship-thru

KZ R – vehicle within a few days of arrival to dealer (also first move to rail station)

KZ S – second move To rail station

KZ T – second rail departure

KZ U – second rail arrival

KZ X – delivered to dealer

KZ Y1 – major damage – must not be sold as new

KZ Y2 – major damage – vehicle sold at auction